Quality Policy

We are committed to supply TMT Reinforcement bars, MS Round bars, Steel Angles, Flat Irons, I Beams and Channel Irons to meet customer and other interested party requirements to achieve the highest level of satisfaction.

We comply with all applicable legal, regulatory and ISO 9001:2015 requirements.

We shall review our Quality Management System, through effective communication to achieve continual improvement.

Achieve success through the teamwork of well trained and disciplined employees and a group of reliable external providers.

Continuously remain in pursuit of achieving excellence.

Our Products

TMT Bars

The Product TMT Steel Bars are available in sizes of 08- 40mm diameter, having high Yield Strengt...

Read more

MS Angles

Tension free rolling ensures uniform dimensional tolerances. Better surface finish and negative s...

Read more

MS Round bars

Produced for varied engineering applications to precise design and dimensions. Superior finish an...

Read more

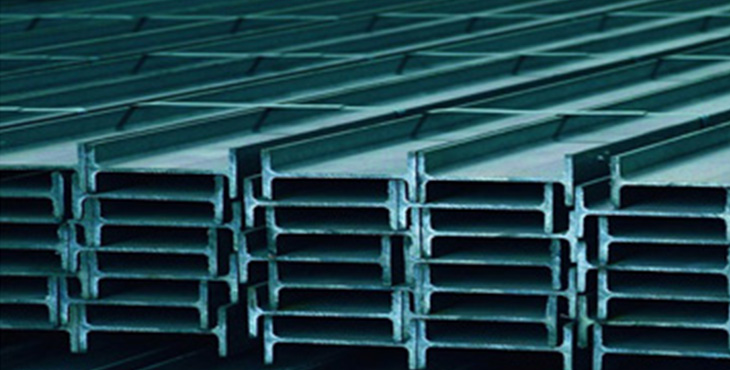

MS ‘I’ Beams

I Beams are used for manufacturing of truck-trailers, EOT cranes and its Gantry, ship building, f...

Read more

MS Channel

Tension free rolling ensures uniform dimensional tolerances. Better surface finish and negative s...

Read more(We can manufacture and supply above products as per customer requirement)

Production Process

Raw Material

‘Captain’ brand products are manufactured using high-quality raw material (Steel Billets) sourced from prime steel mills abroad. The main sources of raw materials for ‘Captain’ brand products are from countries such as India, Ukraine, China, and Indonesia. One of its’ key suppliers of steel billets is Rashtriya Ispat Nigam Ltd popularly known as VIZAG steel which is an Indian Government owned enterprise.

Production Process

Imported prime steel square billets are heated in re-heating furnace at controlled temperatures. After ejecting from the furnace they were rolled through a series of mill stands reducing the sizes to form the steel bars in standard diameters as approved by SLSI. As soon as the bars leave the final stand, they passes through the heat chamber where they are subject to ‘thermex thermo mechanical process’ to quench the steel to achieve the desired result of finished TMT steel bars of grade RB 500. In unit I the production process is manual where as in Unit II it is automated. The production process at both units is confirmed to SLS/ISO 9001:2015.

Quality of Products

Its’ quality assurance plan (QAP) has been recognized by SLSI. Regular testing of ‘Captain’ brand products in respect of chemical and physical properties at own laboratories located at both units ensures the quality consistency of its products. Also, independent testing of its products by the clients at independent laboratories such as the University of Moratuwa, University of Peradeniya, National Building Research Organization (NBRO), Sri Lanka Railway (Rathmalana) and Industrial Technology Institute (ITI) further verifies the quality of its products.